Set-up

Some pages to set-up the line in its main portions are planned to make the S.C.A.D.A easy re-usable for future applications and re-adaptable in case of revisions.

- Tank quantity and type

- The quantity of transporters

- The quantity and type of rectifiers

- Multiple rinses: number and location

- Dosing pumps and the locations where they are used

- Number of temperature controls and their operating locations

Article Database

To maintain the typical treatment data of each article, an articles database can be created:

- Number of parts

- Completion is required

- Time to dip in all of the electrolytic baths

- The electrolytic baths’ currents

- The flight bars are loaded to perfection.

- Surface area of each item (calculated)

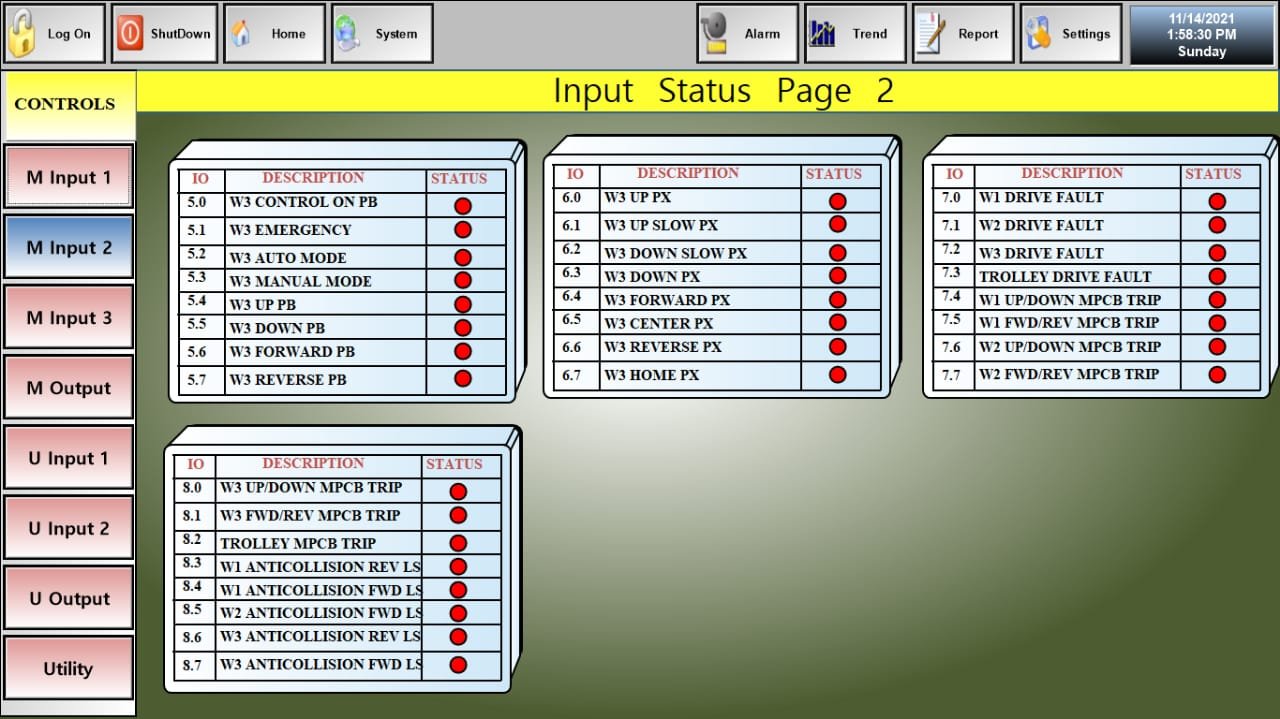

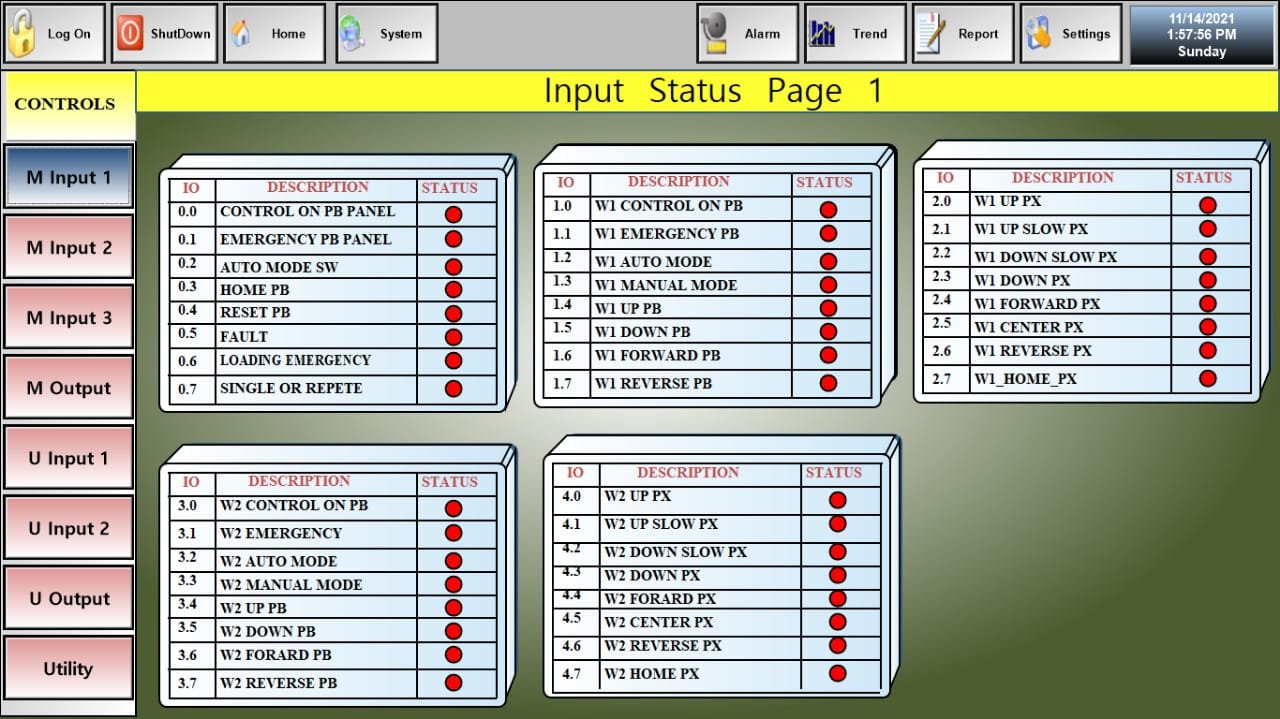

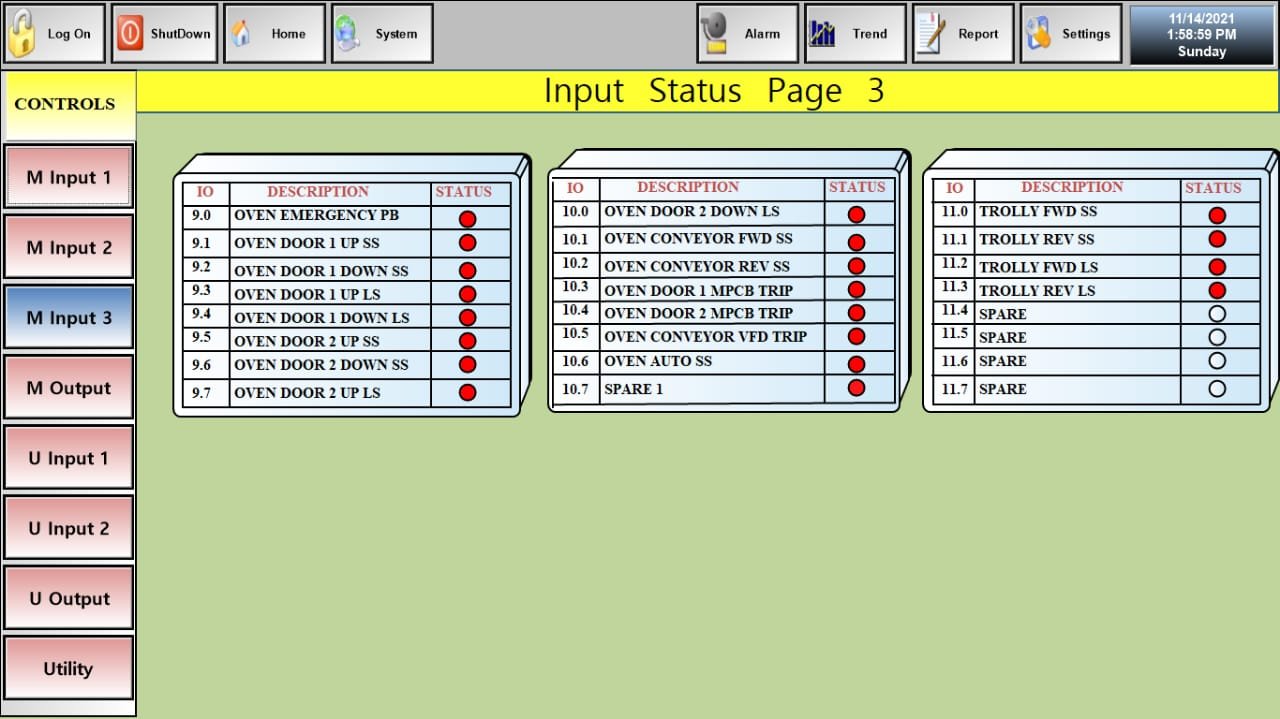

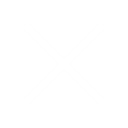

Plant Monitoring

The layout of the line, including the location of the transporters, flight bars, and other items, is shown on this page.

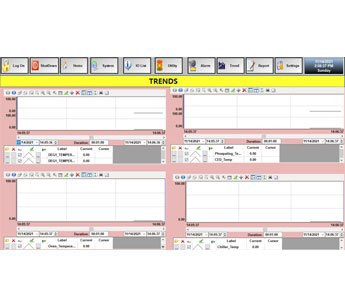

Temperatures

The temperature values are dynamically shown in a graphical or tabular format. It is possible to set the alert thresholds (min. and max.) as well as the working value. All temperature data is recorded in the database and can be viewed in a graphical or tabular style.

Rectifiers

The S.C.A.D.A. can communicate with the rectifiers.

The main page lists all of the rectifiers and displays the stress and current values. The working parameters of each rectifier are extracted from the items database, ensuring perfect working conditions for each processed rack or barrel.

The pH metre installed on the PC can be connected in the same way. The database contains all of the information on the rectifiers, which may be viewed in graphical or tabular format.

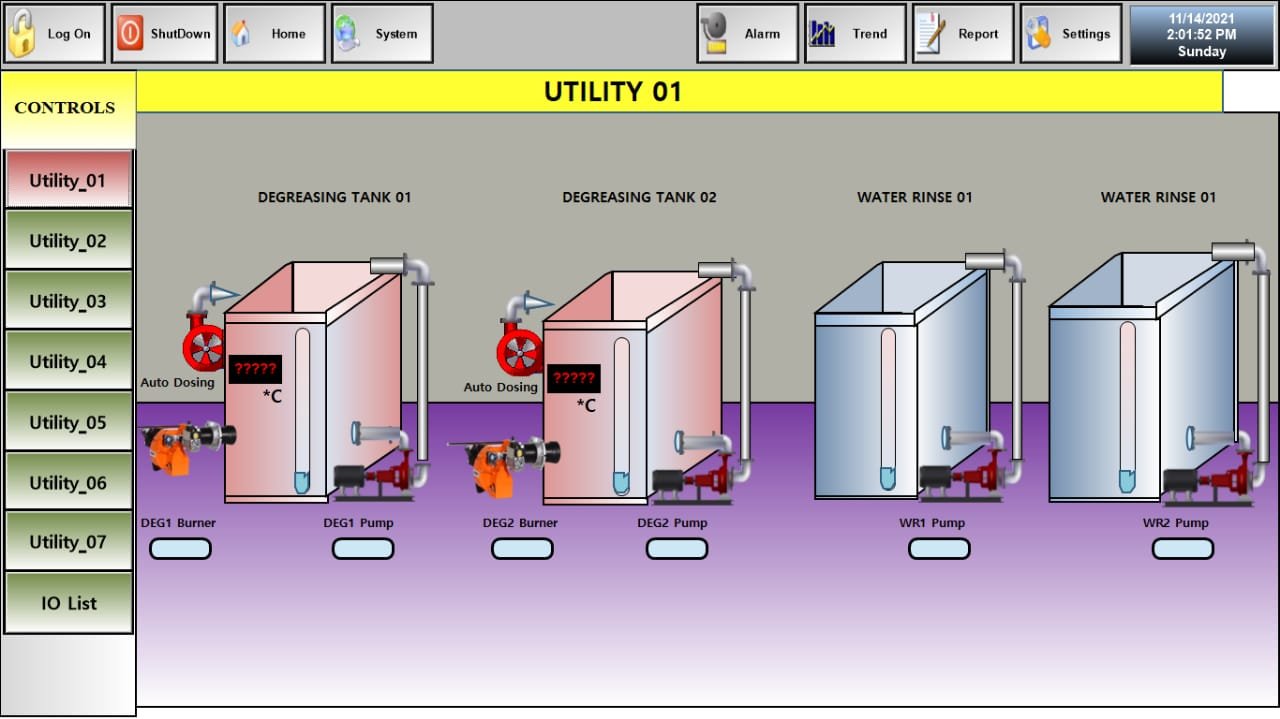

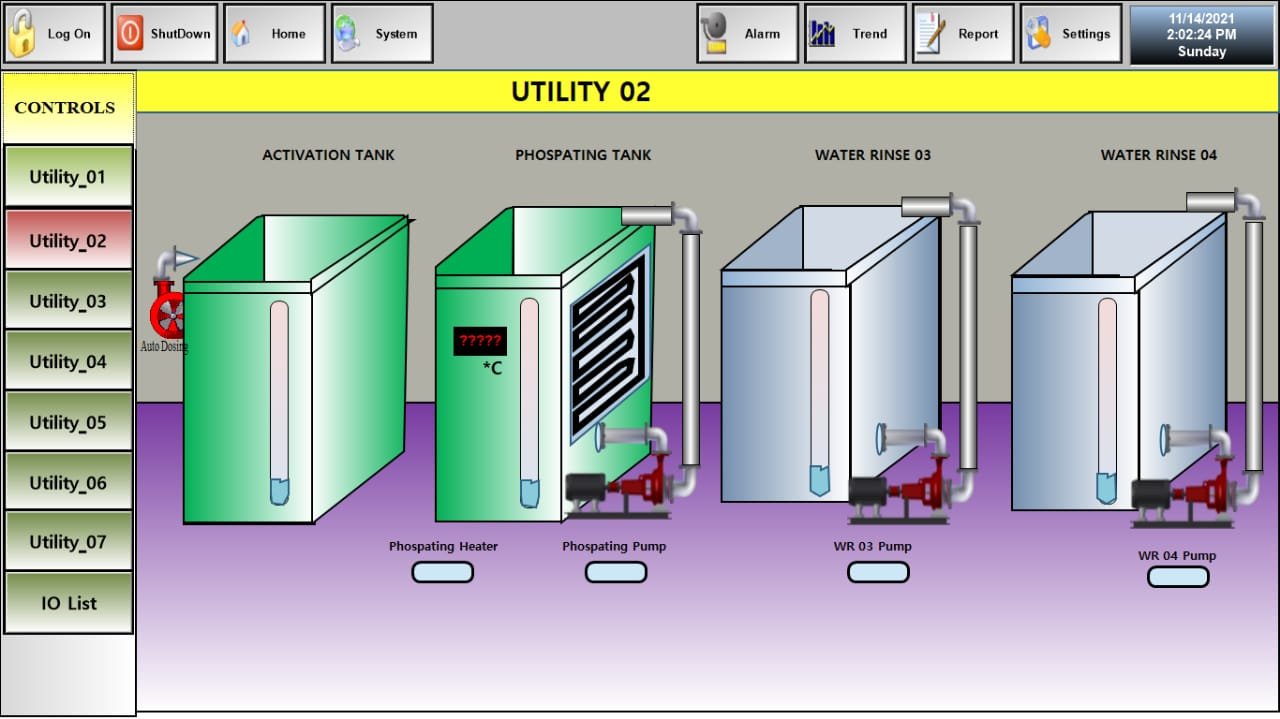

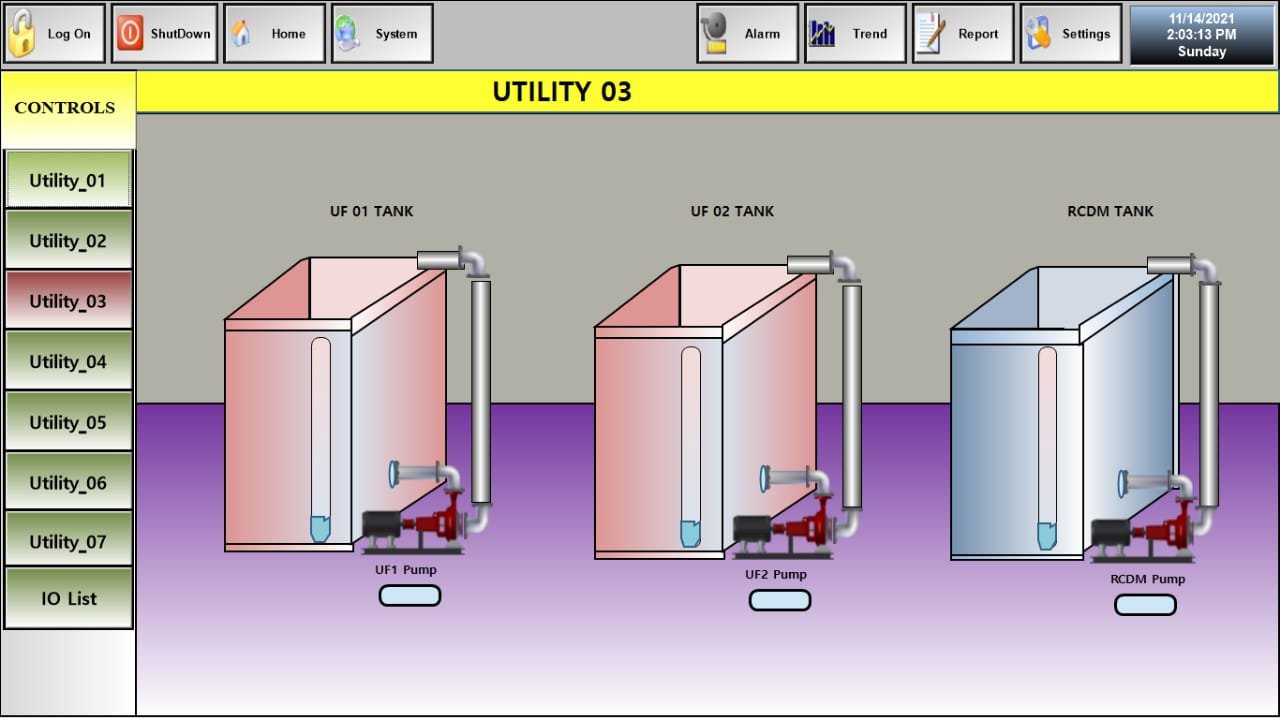

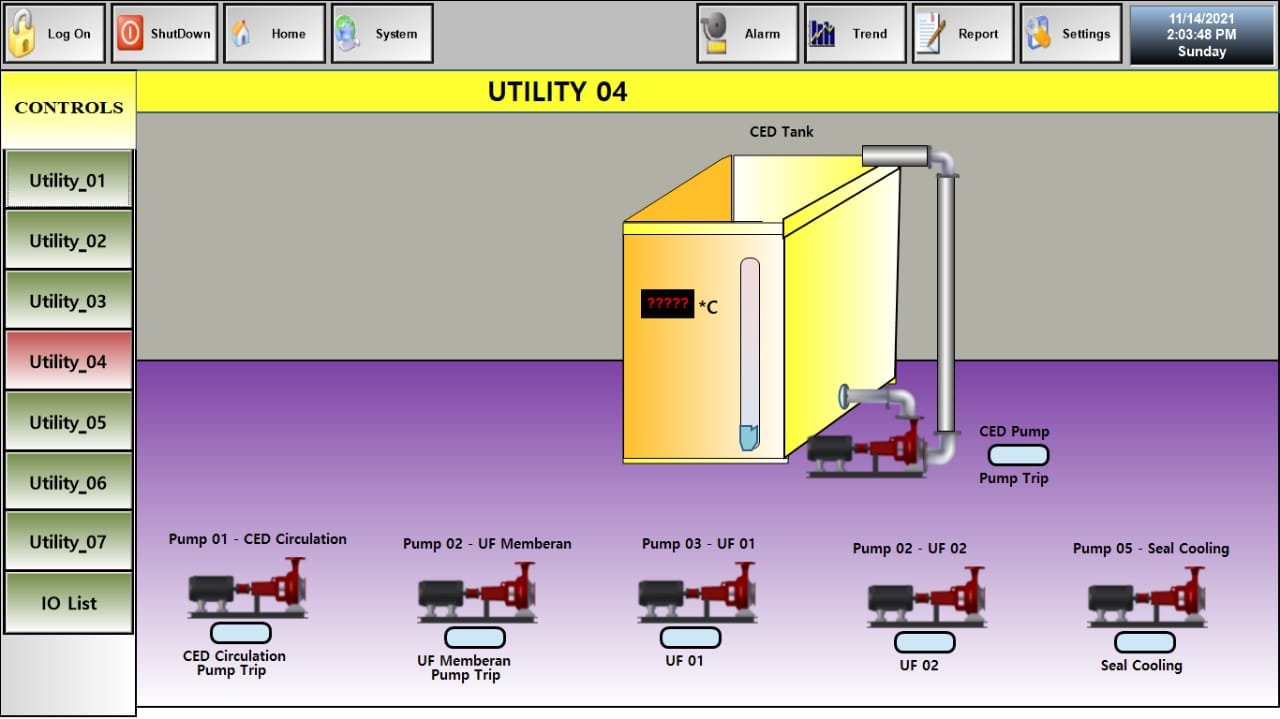

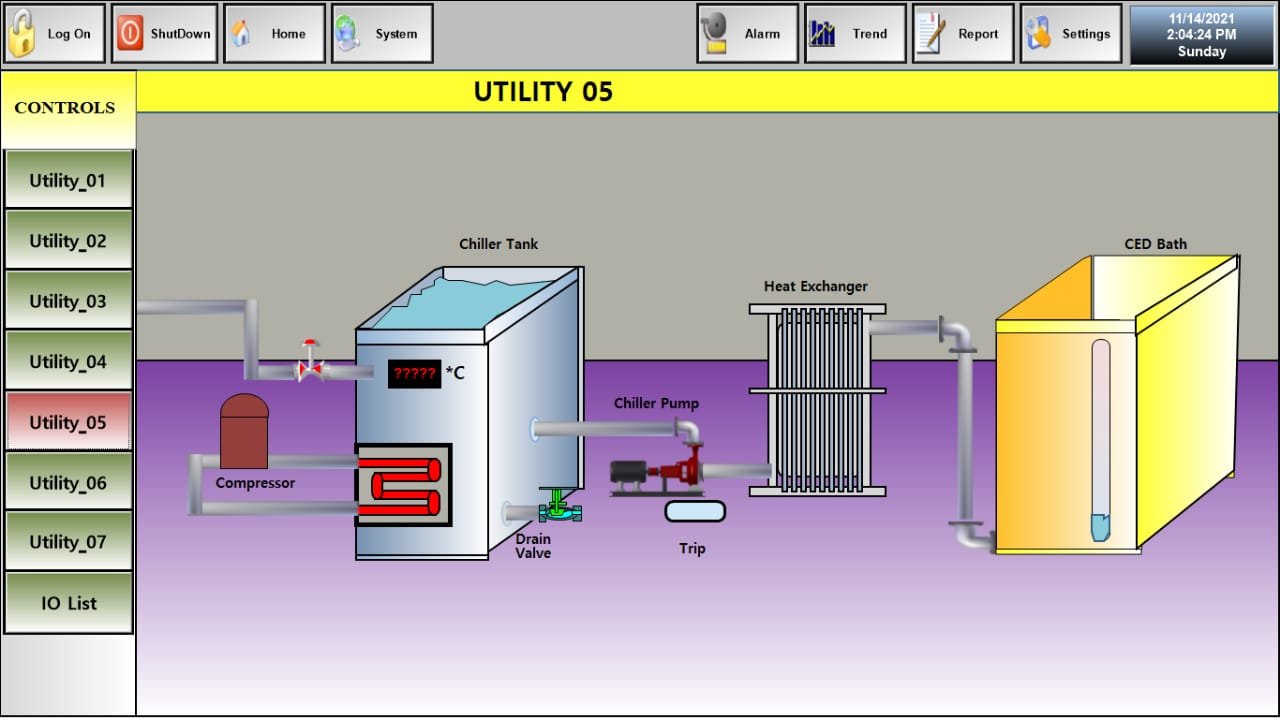

Utilities

The Utility can be customised by changing the following settings:

- The working criterion

- The amount of material that will be added to the baths.

- The utility operation is dynamically displayed, indicating whether the instruments are on or off.

- Following each addition, the value will be recorded and analysed for statistical process control.

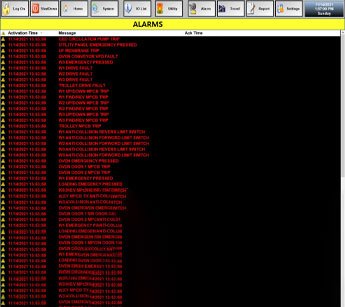

Alarms

Alarms are managed in accordance with the ISA 1A standard, including auditory and bright alerts, as well as thorough visual indication.

Even after a lengthy period of time, the alert database can be reviewed.

Process information

The supervisory database allows you to obtain all information about:

- Analysis of rejection with therapy quality control

- Cycle tracking for each article

- Each process tank’s usage percentage