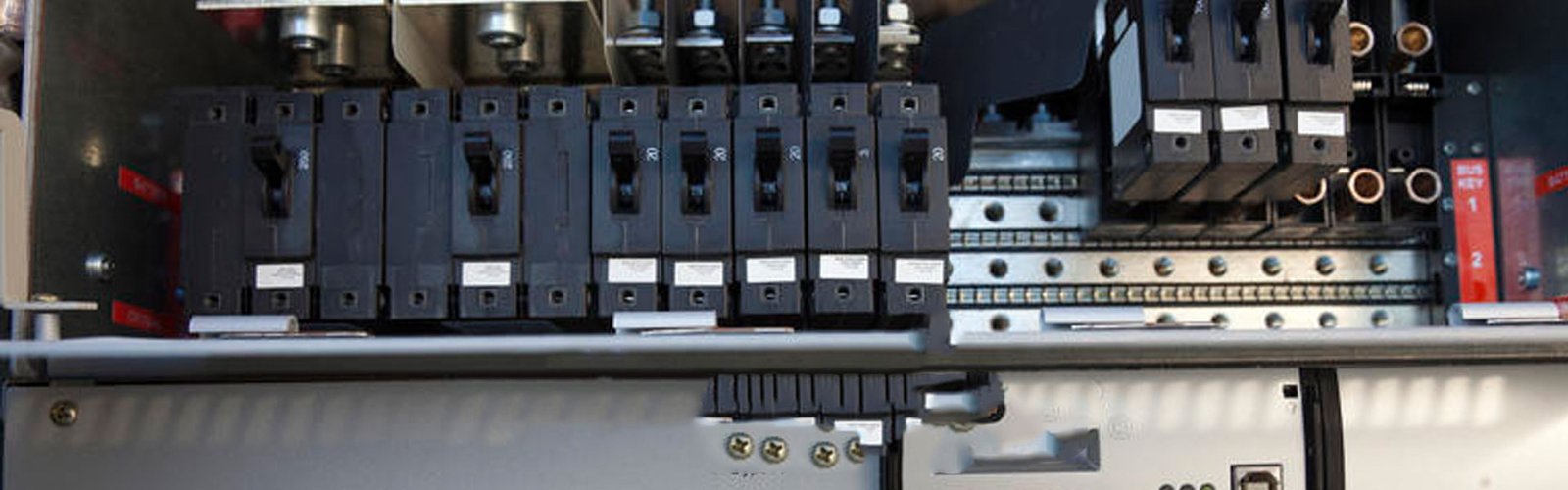

DC-Rectifiers

Electronic or switching technologies can be used in rectifiers.

Tension and current can be controlled and regulated using remote controls (located near the tanks or inside the electric board) or the supervision computer directly. The rectifiers can also be connected to dosing systems for automatic solution top-up.

Filtration System

Some baths require regular or continuous filtration.

The filtering system we propose includes a magnetic pump and either a cartridge or plate unit. The flow rate can range from 1.000 to 40.000 l/h, with filtration levels ranging from 1 to 100 microns.

Tin Anodes

Submerging the tin anodes and the metal portion that will be coated in an electrolyte solution is the process of electroplating with tin anodes. The liquid is then exposed to an electrical current. The positively charged anode electrode will be connected to the tin, while the negatively charged cathode electrode will be connected to the metal.

As it is drawn to the cathode, the DC current along the anode dissolves the tin into the electrolyte solution. Tin is melted, then reduced and put on the metal part. Tin anodes can be electroplated using a variety of techniques.

Jig and Fixtures

A jig is a tool that is used to secure a workpiece or machine part on a workstation. It is attached to CNC machine tools, such as a lathe cutting tool, and controls the location and motion of the tool. That is to say, it acts as a guide for such machining equipment. Jigs are special in that they cause the tool to become immobile when they move.

A fixture, also known as a CNC fixture, is a popular CNC machining tool used to provide stability, support, and positioning. It functions in the same way as the jig in that it secures, supports, or mounts a workpiece on a CNC machine.

Jigs and fixtures are used to hold workpieces and machine parts in place. However, there is a distinction between the two. Turning, milling, grinding, slotting, and other multidimensional operations are all possible with these fixtures. Jigs, on the other hand, are ideal for one-dimensional operations such as counterboring, tapping, drilling, and reaming.

Titanium Baskets

Titanium Anode Baskets from PCB Technologies are made from the highest quality titanium and are extremely robust. Titanium Baskets feature a beautiful finish and are made of solid sheet metal on the sides and base, with welded hooks for good electrical conductivity. Depending on the purpose, anode baskets can be constructed from any grade of titanium.

We create larger, non-standard sizes and spherical baskets at PCB Technologies. Spiral anode baskets in various lengths, Conforming Anode baskets for Barrel plating, Reel to Reel Plating Baskets, and Special Application Baskets are among the non-standard baskets. We also manufacture titanium hooks and plating accessories for a wide range of plating applications.

PCB Technologies is a leading manufacturer and supplier of anode baskets for zinc, copper, chromium, nickel, and tin plating applications. Try our anode baskets to help you achieve consistently uniform plating thickness and increased plating efficiency. If your Anode Basket requirements require something other than typical setups, please contact our technical staff, who can provide alternatives and custom basket options.

Heating and Cooling Coils

Before sending the coolant gas or liquid to another component of the heating and cooling system, these coils raise or lower the temperature and pressure. The system takes hot air into the system during the summer months, cools it, and then distributes it around your home.

Many commercial and industrial applications rely on heating and cooling coils. For more than three decades, PCB Technologies has been designing and producing coils for quick heat transfer.

We make heating and cooling coils for a wide range of industrial and commercial applications. Our coils are divided into three categories based on the heat transfer medium: water, steam, and refrigerant. We now provide a selection of electric heater batteries for complete heating flexibility.

We provide a cost-effective way of extending the life of existing air plant by replacing and repairing coils in existing air handling units or ducted systems, as well as free site studies for replacement or broken coils that cannot be removed from the system.

We’re here to help you every step of the way, with technical experience in heat transfer, a dedicated product manager, BIM objects for all coil products, and industry-leading self-selection software.